For this reason it is applicable to concrete made with relatively dense aggregate particles and requires determination of the aggregate correction factor see 6 1 and 9 1.

Air meter test concrete procedure.

Take your sampled concrete sampled according to astm c172 and mix it up thoroughly.

Once the valve is depressed and held equalization occurs when the known air in the air chamber releases into the unknown air content in the concrete sample in the bowl below.

Astm c231 procedure wipe down the inside and rim of the measuring bowl and the cover with a wet rag to ensure that the pressure meter seals.

H 2795p volumetair air meter.

Pkf construction on turnpike i 95 concrete technician.

H 2796a roll a meter air indicator.

The astm test method for pressure air measurement specifies two meters to measure the air content.

Unscrew cap allow 2 min.

Determine air content specific gravity and free moisture test of aggregates.

Press ur meter concrete air meter.

Astm method of air content measurement in concrete.

To measure the air content of the concrete the upper chamber is pressurized and then the volume of air is released into the lower chamber.

This aluminum roll a meter is used to determine the air content of concrete mixes containing lightweight aggregate.

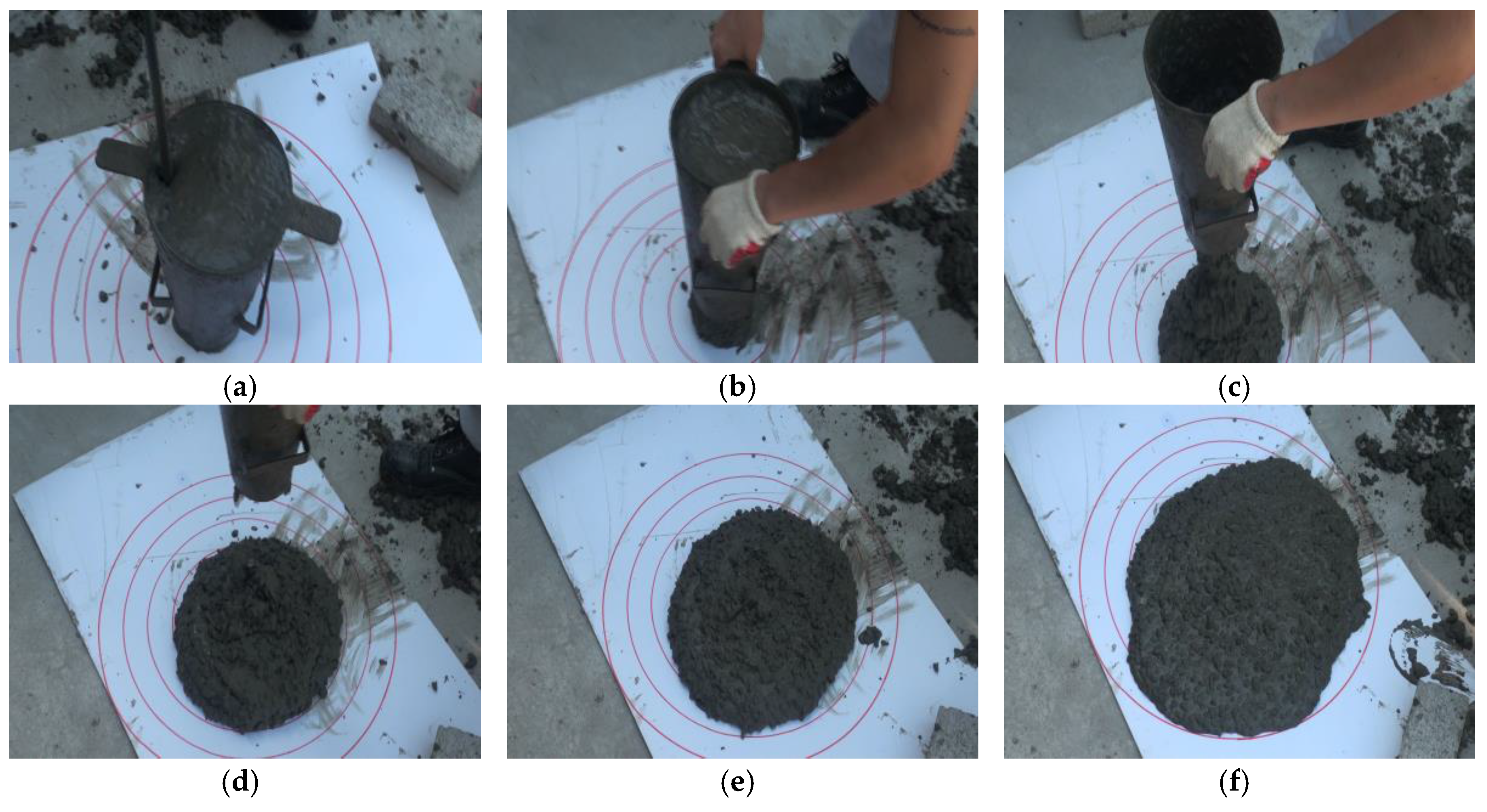

Fill the mold in three equal layers by volume not by height.

Used for the rolling method of measuring entrained air in any concrete.

Once the concrete sample has been remixed start taking the slump tests within 5 minutes.

To settle and take initial reading to the nearest 25 percent.

The test determines the air content of freshly mixed concrete exclusive of any air that may exist inside voids within aggregate particles.

You will put in 3 layers of equal.

Tighten cap and repeat 1 minute roll then loosen cap let settle and take second reading.

If second reading does not differ more than 25 percent from initial reading then second reading becomes the final reading.

Strike off the excess concrete.

Start by filling a mold 12 inches high in the shape of the frustum of a cone that is 8 inches in diameter at the bottom and 4 inches in diameter at the top.

This is carried out by means of a column of water over the known volume of concrete.